Scalable green hydrogen. Simplified!

At XINTC we produce premium quality, innovative Electrolyser Systems that meet the needs of our customer base,

ranging from 600 kW to 100+ MW. Fully integrated and plug-and-play.

Advanced Alkaline Electrolysis (AAE)

XINTC has re-engineered conventional alkaline technology into a modular system that eliminates the need for complex EPC processes. This approach lowers costs, reduces lead times, and simplifies large-scale hydrogen deployment.

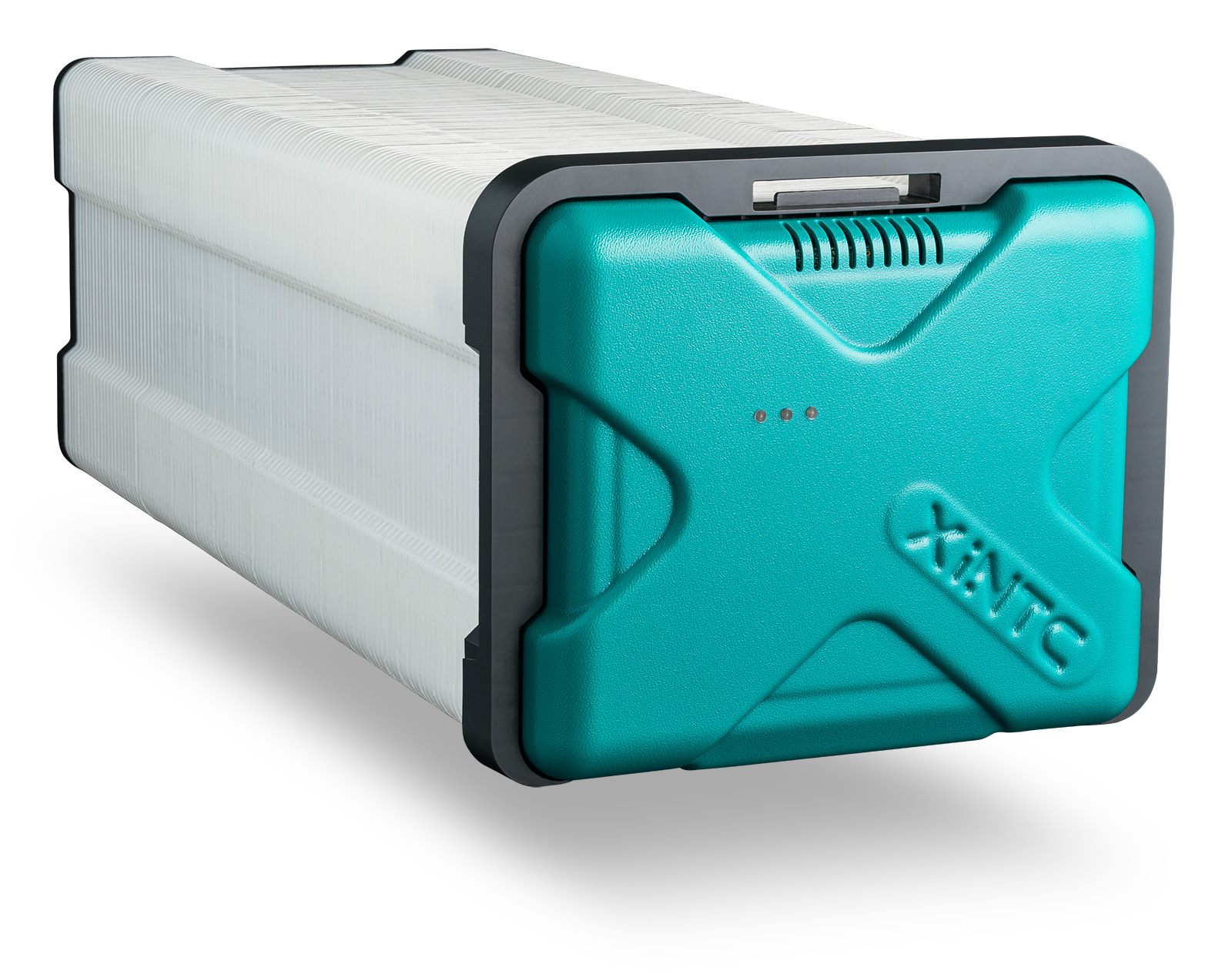

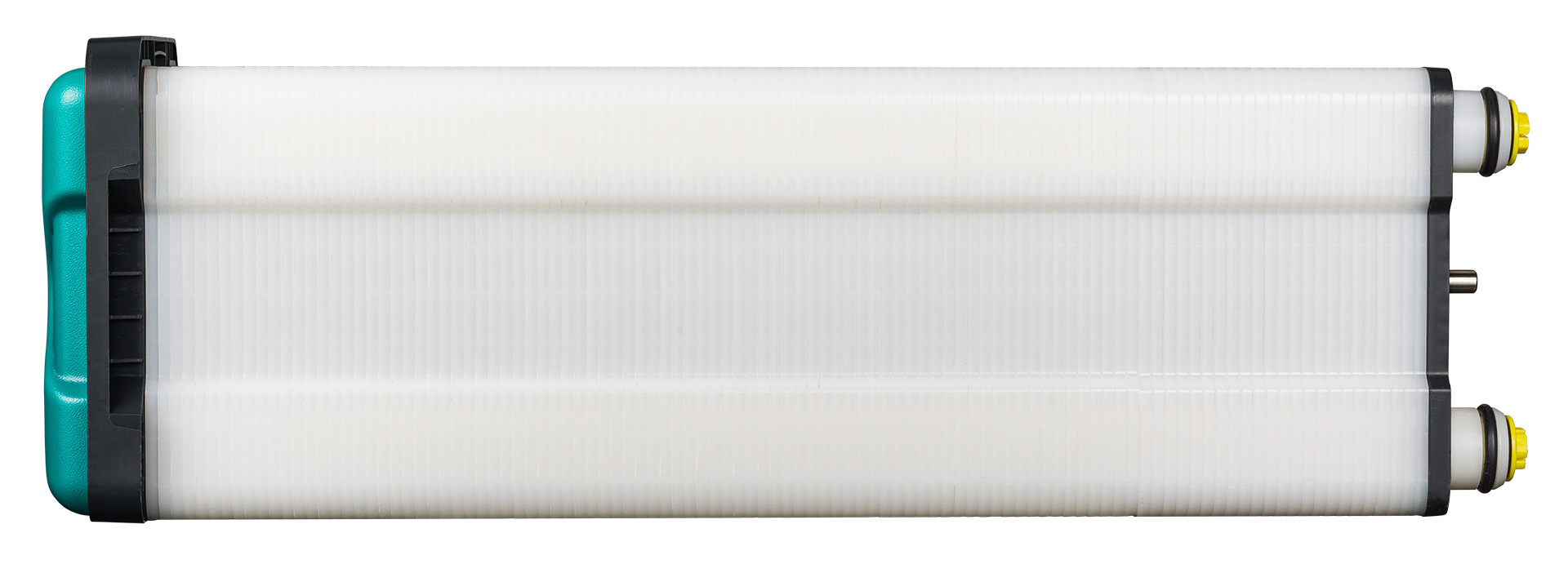

5-6.5 kW Gas Module

LONG SERVICE LIFE and HIGH INTRINSIC SAFETY

Our Gas Modules (stacks) are engineered for extreme flexibility and longevity. Tested beyond 100.000 switch cycles, they handle intermittent renewable power flawlessly without measurable performance loss. Ideal for direct solar and wind coupling, they eliminate the need for buffer systems or complex power management.

Resilient stack design: 100.000+ On/Off cycles.

- HIGH-PERFORMANCE POLYMERS

- NO CRITICAL MATERIALS

- NO MEMBRANES

- NO GASKETS

- FLUID & GAS TIGHT

- SMART ELECTRONICS

- RECYCLABLE

- COMPLYING WITH INTERNATIONAL TECHNICAL STANDARDS

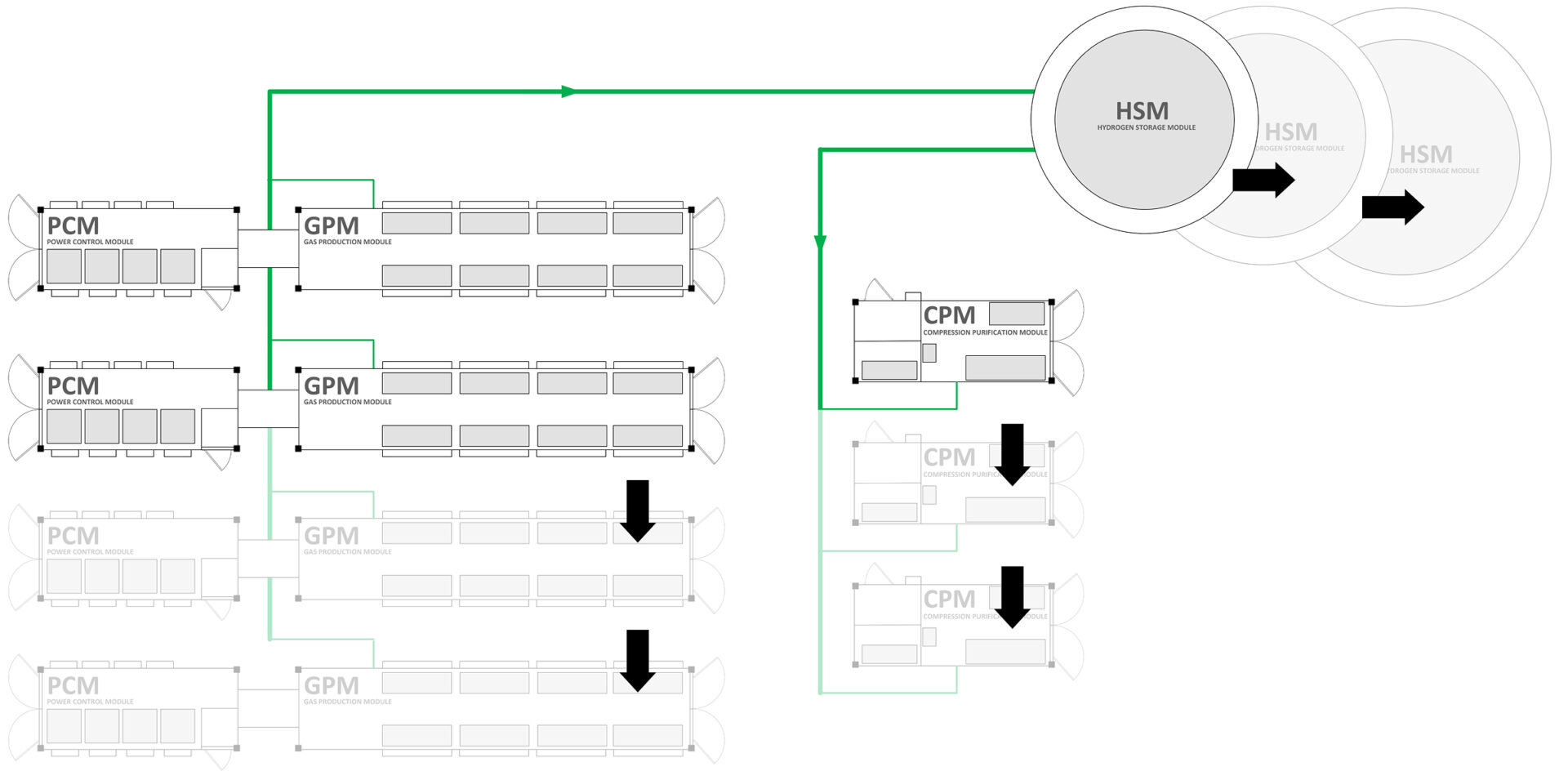

Each Gas Module accomplishes an individual task,

all Gas Modules together deliver a collective performance.

A perfect product-market fit.

FLEXIBLE POWER SUPPLY

SCALABLE CAPACITY

LOW MAINTENANCE

FLEXIBLE USE

SMART ELECTRONICS

Multiple (intermitting) power sources, full dynamic operation

Thoughtfull product architecture, smooth assembly with distinct functional units

Little wear parts,

long running time components,

automated process control,

no critical materials

Numerous application, varying hydrogen quality and output pressure

Both individually and collectively controlled electrolyser modules, high system security

XINTC Electrolyser Systems allow direct coupling with intermittent power sources and are fully equipped for dynamic operation.

No curtailment. No power limits.

Unlock over 20% more hydrogen yield per square meter of photovoltaic panels. XINTC captures every watt of available solar power, even under rapidly fluctuating conditions.

XINTC Electrolysers produce hydrogen in grade 2.5 to grade 5.0 and from atmospheric pressure up to 350 bar by linking function-specific process modules.

XINTC Modular Electrolyser Systems play a key role in accelerating the shift to net zero by enabling local hydrogen production from solar, wind or surplus grid power.

With low-cost, plug-and-play deployment and minimal infrastructure, they make green hydrogen scalable, practical and immediately accessible.

A flexible, modular approach, built to scale with evolving demand.

XINTC develops and manufactures all systems in-house, using only AAA grade components, which guarantees consistent quality, long-term reliability, and full control over every aspect of system performance.

XINTC has clear cost advantages and capability to further decrease LCOH, both in OPEX and in CAPEX.

The concept of XINTC is based on sustainable and responsible use of materials and the principle of good enough design.

- Fit-for-purpose design, no unnecessary complexity

- Controlled in-house production process

- Built to last with minimal material and component degradation

- Stable performance under varying ambient conditions

- Insensitive to external fluctuations

- Minimizes the impact of operational variation

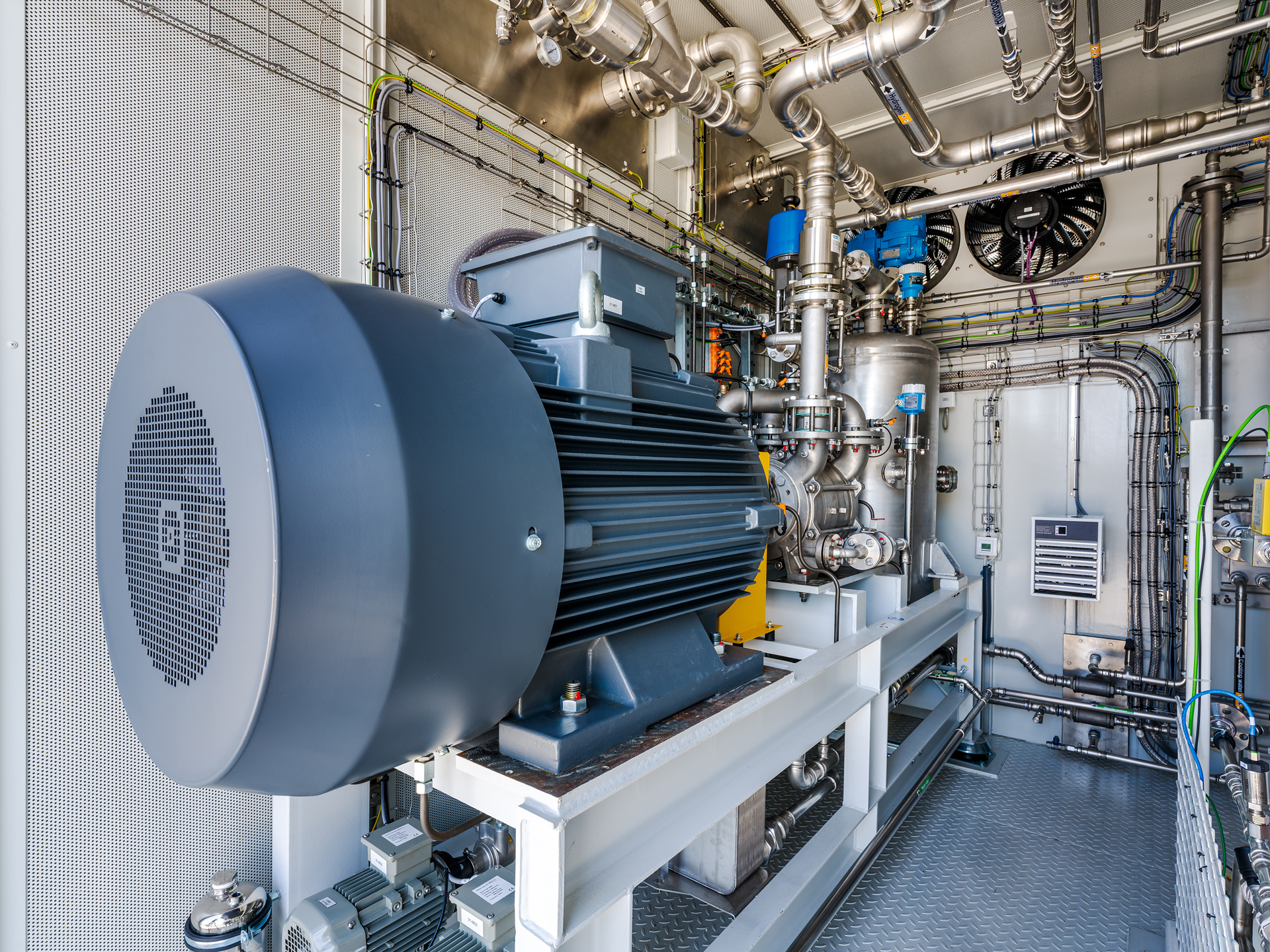

All XINTC Electrolysers come as high cube compartmentalized containerized units.

Each production enclosure accommodates up to 8 system sections, accumulating to 1.2 MW nominal capacity

(AC and/or AC+DC) and 1.6 MW peak (DC only).

Configurable output parameters.

XINTC offers maximum flexibility in capacity, pressure, and gas purity. The standard setup includes a Power & Control Module and a Gas Production Module, delivering hydrogen at minimum 99.5% purity and 0.5 bar(g). For higher pressure or purity requirements, up to 99.999% (fuel grade) and 13 bar(g), a Compression & Purification Module can be seamlessly added.

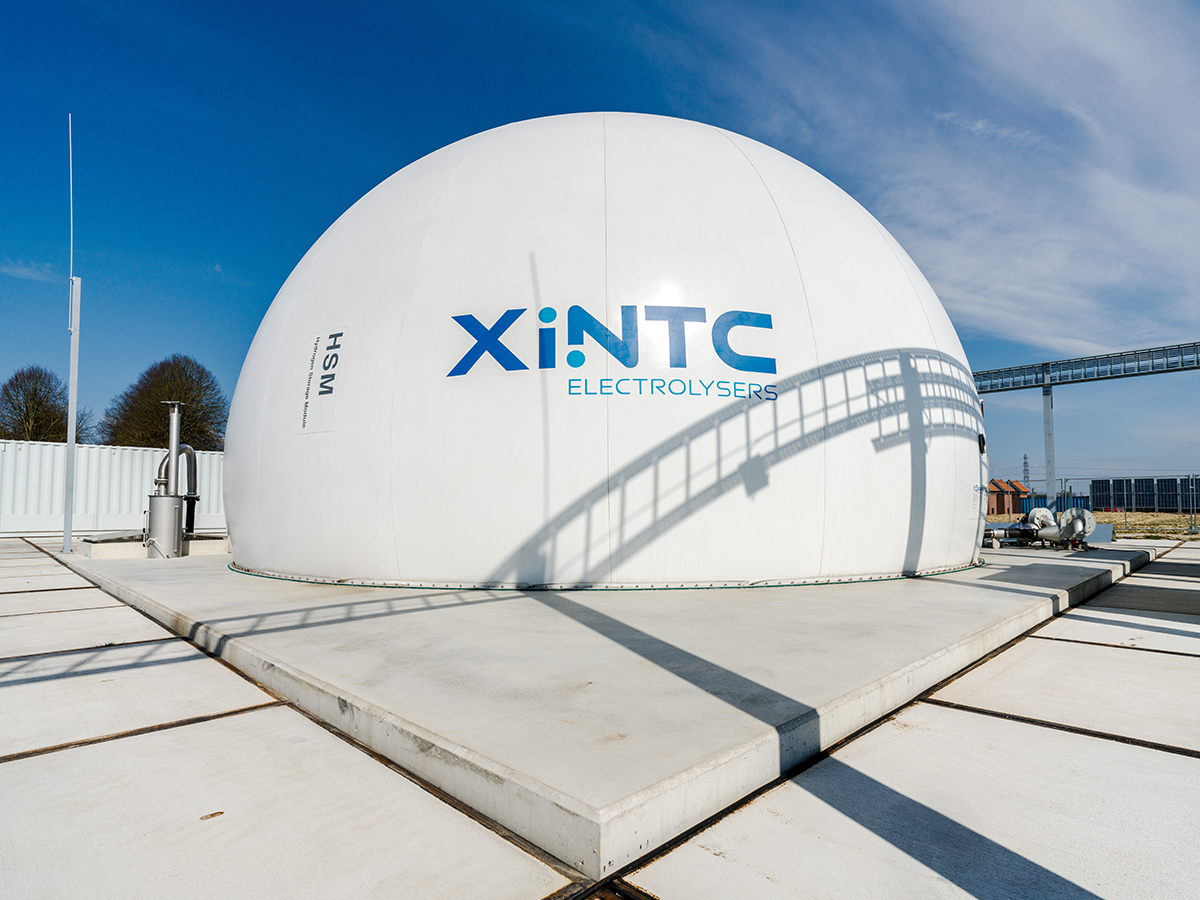

The HSM offers a unique, economical solution for safe, low-pressure storage of hydrogen from 150m³ up to 10.000m³. Its triple-layer polymer membrane, paired with smart sensors, safety valves, and ATEX ventilation, ensures reliable performance.

FREE CONFIGURATION & SCALABLE CAPACITY.

Our people are driven by motivation to design products that minimize the total cost of ownership.